Purpose Of Brushes In Motors . Carbon brushes, or electric motor brushes, play an important role in motors and generators, serving as electrical conductors. Brushes in electric motor conduct electricity that makes the motor spin. This is achieved by passing electrical current between the motor’s stationary and rotating wires. The stator contains either permanent magnets. Motor brushes are a fundamental component of many electric motors, particularly those classified as brushed dc motors. Brushed dc (bdc) motors have four main parts: For a start, it transmits an electrical current. Brushed dc motor working principle. Learn the basics of what brushes are made of, how they work, and how they wear out over time. When power supplies to the motor through battery or any dc source, electricity flows from the source to the armature through the brushes which. The carbon brush is a critical component of a dc motor for many reasons. Brushed dc motors work by having the coil rotate inside the surrounding magnets. Stator, rotor, commutator, and brushes. The purpose of carbon brushes in dc motors. Dc motors are divided into brushed dc motors and brushless dc motors.

from opereviews.com

Carbon brushes, or electric motor brushes, play an important role in motors and generators, serving as electrical conductors. Motor brushes are a fundamental component of many electric motors, particularly those classified as brushed dc motors. Stator, rotor, commutator, and brushes. The carbon brush is a critical component of a dc motor for many reasons. Brushed dc motor working principle. The purpose of carbon brushes in dc motors. The stator contains either permanent magnets. Brushed dc (bdc) motors have four main parts: Learn the basics of what brushes are made of, how they work, and how they wear out over time. For a start, it transmits an electrical current.

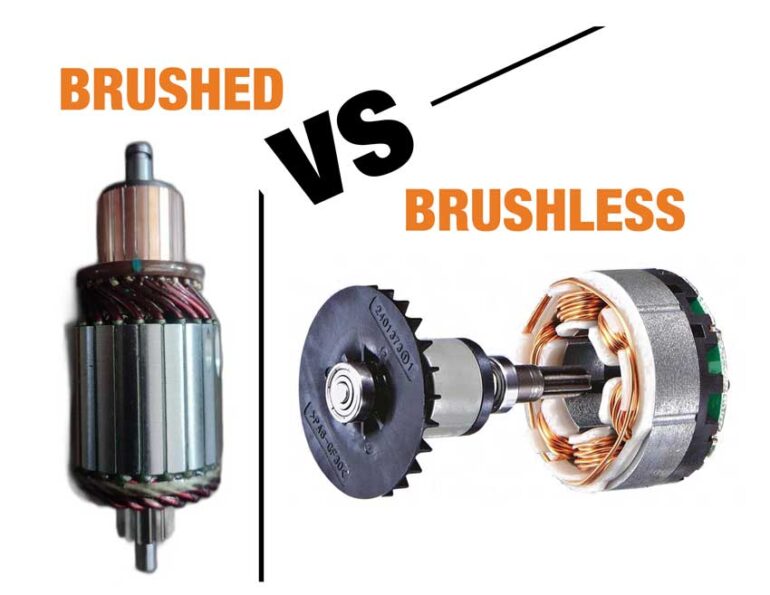

Brushless vs Brushed Motor Technology Explained OPE Reviews

Purpose Of Brushes In Motors Brushed dc motor working principle. For a start, it transmits an electrical current. Stator, rotor, commutator, and brushes. Carbon brushes, or electric motor brushes, play an important role in motors and generators, serving as electrical conductors. Brushed dc motor working principle. Motor brushes are a fundamental component of many electric motors, particularly those classified as brushed dc motors. This is achieved by passing electrical current between the motor’s stationary and rotating wires. The carbon brush is a critical component of a dc motor for many reasons. Dc motors are divided into brushed dc motors and brushless dc motors. Brushed dc motors work by having the coil rotate inside the surrounding magnets. Brushed dc (bdc) motors have four main parts: When power supplies to the motor through battery or any dc source, electricity flows from the source to the armature through the brushes which. The purpose of carbon brushes in dc motors. Brushes in electric motor conduct electricity that makes the motor spin. The stator contains either permanent magnets. Learn the basics of what brushes are made of, how they work, and how they wear out over time.

From www.surplussales.com

Motor Brushes Purpose Of Brushes In Motors Dc motors are divided into brushed dc motors and brushless dc motors. Brushed dc motor working principle. The stator contains either permanent magnets. Stator, rotor, commutator, and brushes. Brushes in electric motor conduct electricity that makes the motor spin. Motor brushes are a fundamental component of many electric motors, particularly those classified as brushed dc motors. This is achieved by. Purpose Of Brushes In Motors.

From www.grainger.com

DAYTON Motor Brush Set, 9/16 In L, 5/16 In W, PK2 10K121M1760032.00 Purpose Of Brushes In Motors Stator, rotor, commutator, and brushes. This is achieved by passing electrical current between the motor’s stationary and rotating wires. Dc motors are divided into brushed dc motors and brushless dc motors. The purpose of carbon brushes in dc motors. Brushed dc motor working principle. For a start, it transmits an electrical current. Brushed dc motors work by having the coil. Purpose Of Brushes In Motors.

From www.vrogue.co

Technical Manual Series Types Of Brushless Motors vrogue.co Purpose Of Brushes In Motors This is achieved by passing electrical current between the motor’s stationary and rotating wires. Learn the basics of what brushes are made of, how they work, and how they wear out over time. Brushed dc motors work by having the coil rotate inside the surrounding magnets. The stator contains either permanent magnets. Dc motors are divided into brushed dc motors. Purpose Of Brushes In Motors.

From www.youtube.com

Finding Motor Brushes YouTube Purpose Of Brushes In Motors The stator contains either permanent magnets. Brushed dc motors work by having the coil rotate inside the surrounding magnets. Carbon brushes, or electric motor brushes, play an important role in motors and generators, serving as electrical conductors. Brushed dc (bdc) motors have four main parts: When power supplies to the motor through battery or any dc source, electricity flows from. Purpose Of Brushes In Motors.

From www.walmart.com

4 Pcs Replacement Motor Carbon Brushes 13mm x 7mm x 6mm for Electric Purpose Of Brushes In Motors For a start, it transmits an electrical current. This is achieved by passing electrical current between the motor’s stationary and rotating wires. The stator contains either permanent magnets. Stator, rotor, commutator, and brushes. Brushes in electric motor conduct electricity that makes the motor spin. Motor brushes are a fundamental component of many electric motors, particularly those classified as brushed dc. Purpose Of Brushes In Motors.

From solonz.co.nz

Brushed motors vs brushless motors what's the difference? Solo New Purpose Of Brushes In Motors This is achieved by passing electrical current between the motor’s stationary and rotating wires. When power supplies to the motor through battery or any dc source, electricity flows from the source to the armature through the brushes which. For a start, it transmits an electrical current. Brushed dc motors work by having the coil rotate inside the surrounding magnets. Brushed. Purpose Of Brushes In Motors.

From www.walmart.ca

4 Pcs Replacement Motor Carbon Brushes 13mm x 8mm x 5mm for Electric Purpose Of Brushes In Motors The purpose of carbon brushes in dc motors. For a start, it transmits an electrical current. The carbon brush is a critical component of a dc motor for many reasons. The stator contains either permanent magnets. Brushed dc (bdc) motors have four main parts: When power supplies to the motor through battery or any dc source, electricity flows from the. Purpose Of Brushes In Motors.

From www.youtube.com

Grinder Repair Replacing Carbon Motor Brushes (Makita Part CB325 Purpose Of Brushes In Motors Brushed dc (bdc) motors have four main parts: Stator, rotor, commutator, and brushes. The purpose of carbon brushes in dc motors. Learn the basics of what brushes are made of, how they work, and how they wear out over time. Brushed dc motors work by having the coil rotate inside the surrounding magnets. Carbon brushes, or electric motor brushes, play. Purpose Of Brushes In Motors.

From www.globalspec.com

Brushed DC Motor Working Principle GlobalSpec Purpose Of Brushes In Motors Carbon brushes, or electric motor brushes, play an important role in motors and generators, serving as electrical conductors. Learn the basics of what brushes are made of, how they work, and how they wear out over time. For a start, it transmits an electrical current. This is achieved by passing electrical current between the motor’s stationary and rotating wires. When. Purpose Of Brushes In Motors.

From www.youtube.com

What is the use of Carbon brushes in motor Advantages of carbon Purpose Of Brushes In Motors When power supplies to the motor through battery or any dc source, electricity flows from the source to the armature through the brushes which. The carbon brush is a critical component of a dc motor for many reasons. Motor brushes are a fundamental component of many electric motors, particularly those classified as brushed dc motors. The stator contains either permanent. Purpose Of Brushes In Motors.

From www.walmart.ca

2 Pcs Replacement Motor Carbon Brushes 10 x 5 x 5mm for Electric Motors Purpose Of Brushes In Motors Brushed dc (bdc) motors have four main parts: The purpose of carbon brushes in dc motors. Carbon brushes, or electric motor brushes, play an important role in motors and generators, serving as electrical conductors. Brushes in electric motor conduct electricity that makes the motor spin. This is achieved by passing electrical current between the motor’s stationary and rotating wires. Brushed. Purpose Of Brushes In Motors.

From www.ebay.co.uk

Cleaner Head Brush Bar Brushroll Motor For Dyson DC25 DC41 Vacuum Purpose Of Brushes In Motors Stator, rotor, commutator, and brushes. The stator contains either permanent magnets. The carbon brush is a critical component of a dc motor for many reasons. Motor brushes are a fundamental component of many electric motors, particularly those classified as brushed dc motors. Brushed dc motors work by having the coil rotate inside the surrounding magnets. Dc motors are divided into. Purpose Of Brushes In Motors.

From canada.newark.com

148867 Maxon Motor, DC Motor, RE40, Graphite Brushes Purpose Of Brushes In Motors Dc motors are divided into brushed dc motors and brushless dc motors. For a start, it transmits an electrical current. Brushed dc motor working principle. Motor brushes are a fundamental component of many electric motors, particularly those classified as brushed dc motors. Brushed dc (bdc) motors have four main parts: Carbon brushes, or electric motor brushes, play an important role. Purpose Of Brushes In Motors.

From www.autoprecaution.com

Do AC Motors Use Brushes Auto Precaution Purpose Of Brushes In Motors Brushes in electric motor conduct electricity that makes the motor spin. Carbon brushes, or electric motor brushes, play an important role in motors and generators, serving as electrical conductors. Learn the basics of what brushes are made of, how they work, and how they wear out over time. Brushed dc motors work by having the coil rotate inside the surrounding. Purpose Of Brushes In Motors.

From www.walmart.com

Motor Brush Replacement Set 5/8" x 5/16" x 3/16" 5 Pair Purpose Of Brushes In Motors Brushed dc motors work by having the coil rotate inside the surrounding magnets. Stator, rotor, commutator, and brushes. This is achieved by passing electrical current between the motor’s stationary and rotating wires. Brushes in electric motor conduct electricity that makes the motor spin. The carbon brush is a critical component of a dc motor for many reasons. Motor brushes are. Purpose Of Brushes In Motors.

From www.etechnophiles.com

DC Motor Working Principle, Construction and Diagram Explanation Purpose Of Brushes In Motors This is achieved by passing electrical current between the motor’s stationary and rotating wires. Brushed dc motor working principle. Motor brushes are a fundamental component of many electric motors, particularly those classified as brushed dc motors. Carbon brushes, or electric motor brushes, play an important role in motors and generators, serving as electrical conductors. Brushed dc (bdc) motors have four. Purpose Of Brushes In Motors.

From huphaco.vn

Động cơ 1 chiều Động cơ DC Động cơ servo dùng trong công nghiệp Purpose Of Brushes In Motors Brushed dc (bdc) motors have four main parts: Carbon brushes, or electric motor brushes, play an important role in motors and generators, serving as electrical conductors. Brushed dc motors work by having the coil rotate inside the surrounding magnets. Brushed dc motor working principle. Stator, rotor, commutator, and brushes. This is achieved by passing electrical current between the motor’s stationary. Purpose Of Brushes In Motors.

From www.electricity-magnetism.org

Motor Brushes How it works, Application & Advantages Purpose Of Brushes In Motors Dc motors are divided into brushed dc motors and brushless dc motors. This is achieved by passing electrical current between the motor’s stationary and rotating wires. Motor brushes are a fundamental component of many electric motors, particularly those classified as brushed dc motors. For a start, it transmits an electrical current. Brushed dc motor working principle. Stator, rotor, commutator, and. Purpose Of Brushes In Motors.